Houses

use a variety of different temperatures, ranging from the freezer to the

furnace. Different temperatures are best for different applications: frozen

foods, ice cream, milk, vegetables, beverages, fruits, washing your hands,

showering, washing machine, radiators.

Several different appliances supply these different needs,

each dumping heat or cold, or both, through their insulation into the home and

outside.

For example, Refrigerators have 5 major sources of heat

leakage, leading to loss of efficiency:

- Heat given off by the refrigeration cycle

- Heat given off by the Electric Motor

- Heat infiltrating through the insulation

- Heat infiltrating when the Refrigerator door is opened

- Heat brought in by items placed in the Refrigerator

We considered losses #1 and #2 in the previous Post, and

decided we could put this waste heat to good use by using the “waste heat” to

heat water, for example in the Hot Water Heater, or for Space Heating.

Now let’s consider the other 3 types of heat loss.

Heat flow is proportional to the difference in temperature

between the inside and outside of the appliance.

Heat flow is moderated by the effectiveness of the insulation

around the device.

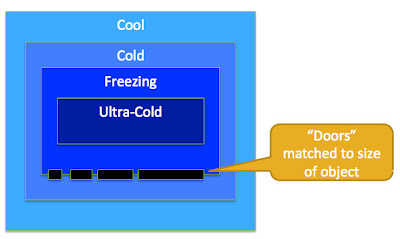

To address loss #3: Nest the storage in concentric temperature

zones so adjacent zones have lower temperature differences than with the

environment, and thus reduce heat loss.

The waste heat from one appliance can help heat, or cool,

the adjacent one. Heat will flow more slowly into a Freezer if the Freezer is

surrounded by the Refrigerator than the room. Similarly, waste heat from the Furnace

can help heat hot water if the Water Heater surrounds the furnace.

To address losses #4 and #5, consider another set of ideas: Optimized

Heating and Cooling Paths.

When you want to put something in the freezer, rather than

opening the door to the room, just open the “door” to the next cooler nested

zone. This reduces loss #4, “opening the door.” Also rather than opening a

“door” to the whole freezing zone, as you do with your freezer today, just open

a “door” large enough for the item to be placed inside or removed.

Small doors don’t work very well when you have to see inside

to find what you want and stick your arm in to retrieve or place the object.

But with Autonomous Vehicles we can match the vehicle to the

size of the object, as we have said already for efficiency in transport.

To reduce loss #5, instead of just taking an object at

whatever starting temperature it has and putting it into the target temperature storage

zone, we can put the object through a separate heating or cooling process to

get it to the target temperature before putting it in the appropriate storage

zone.

The best solutions depend on the details of the situation,

so I’ll give a few examples:

- When you are taking something out of cold storage, you can use the “cold energy” stored in the object to cool successive cooler levels of storage by moving the object at an appropriate speed through successive levels. For example, this works well to thaw an object from the freezer. Similarly if you have very hot water and you want warm water, you can use the heat stored in the hot water to warm successively cooler water.

- To heat an object to a hotter temperature, depending on the sources of various levels of heat, you can move it at an appropriate speed through the successive warmer zones, starting at an appropriate zone based on the temperature of the object.

- For storing cold objects, you can move it at an appropriate speed through the successive colder zones, based on the starting temperature of the object. This reduces the disruption to other items already in storage caused by the object. Some objects may take too long to reach their target temperature, so this may not be appropriate for them; e.g., the food might spoil on the way to its target temperature.

- Another alternative is to have separate chambers to match the heating and cooling needs for particular items. For example, flash freezing is best for some foods; but once frozen the food can be moved to the appropriate storage zone, using the successive zone method if the target temperature is colder or hotter than the temperature achieved with the flash freezing process.

Having people move through these concentric temperature

zones is not reasonable for several reasons: people are big so they need a lot

of space to move; people give off a lot of heat; people also give off humidity

in their breath, and shed hair, skin and other detritus; plus it is

uncomfortable or even dangerous.

Fortunately, Autonomous Vehicles are ideal for moving objects

from one zone to another, to use the heat flows to advantage. We can also have

Autonomous Vehicles with very low thermal mass so they don’t absorb or give off

heat to the storage zones as they pass through.

The Autonomous Vehicles can also take the objects to

separate processes, such as flash freezing, and then move them along the

appropriate path through the Temperature Storage Zones.

If we combine the Nested Temperature Storage Zones,

Optimized Heating & Cooling Paths, and the Heat Transfer Pipe Ideas, we can

capture most of the heat loss from Refrigeration and Heating in our Integrated Heating & Cooling Refrigeration System.

We have now addressed all 5 of the heat loss categories.

Next let’s expand our consideration to other sources of waste heat in homes and

commercial establishments.

No comments:

Post a Comment